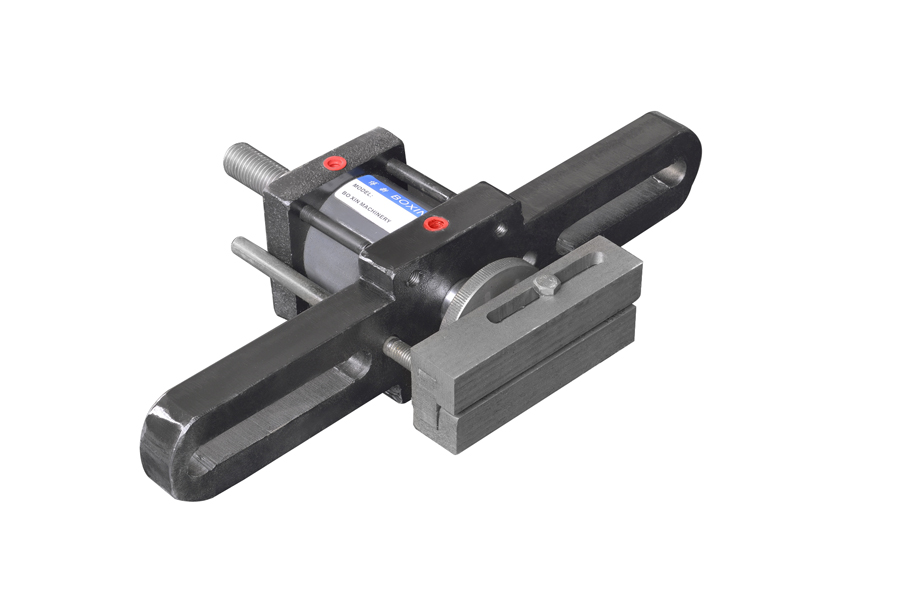

The hydraulic cylinder will gradually have a lot of problems due to the time relationship, so that it can have a great impact on the work, so when we use the worm gear box reducer,What kind of problems occur in hydraulic cylinders and other products should be checked in time so that the problems can be solved well. If they can’t be used at all, then hydraulic cylinder manufacturers will share common failure phenomena and solutions of hydraulic cylinders. Program

(1) The spool valve hole is blocked or blocked.When the valve slide or valve in the flow direction is stuck or blocked, the hydraulic cylinder is prone to malfunction or operation failure.You should check for oil stains, check for dirt or gelatinous deposits or clogged slide valve holes;Worn check valve.

(2) The plug-in of the piston and cylinder or hydraulic cylinder of the card.At this time, no matter how you manipulate it, the hydraulic cylinder moves or moves even slightly.Then check whether the piston and piston rod seals are too tight, whether dirt and colloidal deposits have entered: on the axis of the piston and the cylinder, the wearing parts and seals are invalid.

(3) The pressure of the hydraulic system is too low.The throttling resistance of the control line may be too large, the flow control valve is improperly adjusted, the control pressure is inappropriate, and the pressure source is disturbed.You should check the control pressure source to ensure that the system pressure is adjusted to the specified value.

(4) Air inserted in the hydraulic system.Mainly because of system leaks.You should check the oil level of the hydraulic oil tank, the seals and joints on the suction side of the pump, and the suction strainer is dirty.If this is the case, you should add hydraulic oil, process seals and pipe joints, clean or replace the coarse filter.

(5) The initial action of the hydraulic cylinder is slow.At low temperatures, the viscosity and fluidity of the hydraulic oil are poor, which results in the slow operation of the hydraulic cylinder.Change the viscosity of hydraulic oil - Better temperature performance, by having the machine's own heater or heating oil at low temperatures, to improve start-up improvement.

When these problems occur in the hydraulic cylinder, the above-mentioned methods can be used to solve them, so that we will not have big problems in the process of use, and the service life of the equipment can be extended a lot. of