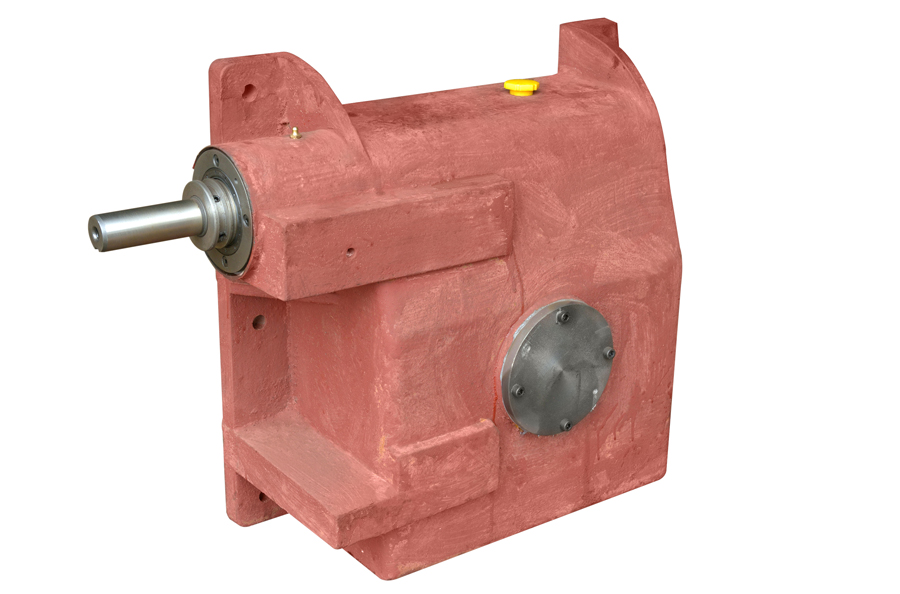

A. Cabinet: In corrosive environments, it is recommended to use stainless steel; in low temperature environments, it is recommended to choose LCB, LC1 and other materials, and in normal environments, choose WCB or GGG45. Compared with ductile iron, WCB has the advantage of greater strength. When the motor speed is high, the box body will not break, and its mechanical properties are better than ductile materials.Of course, there are spheroidal ink grades higher than WCB, but the cost will be higher than WCB.

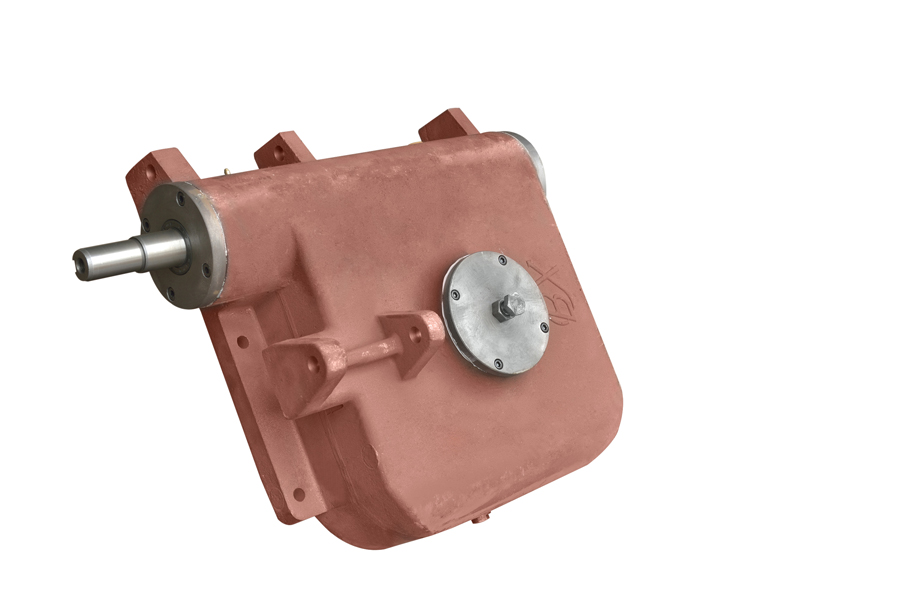

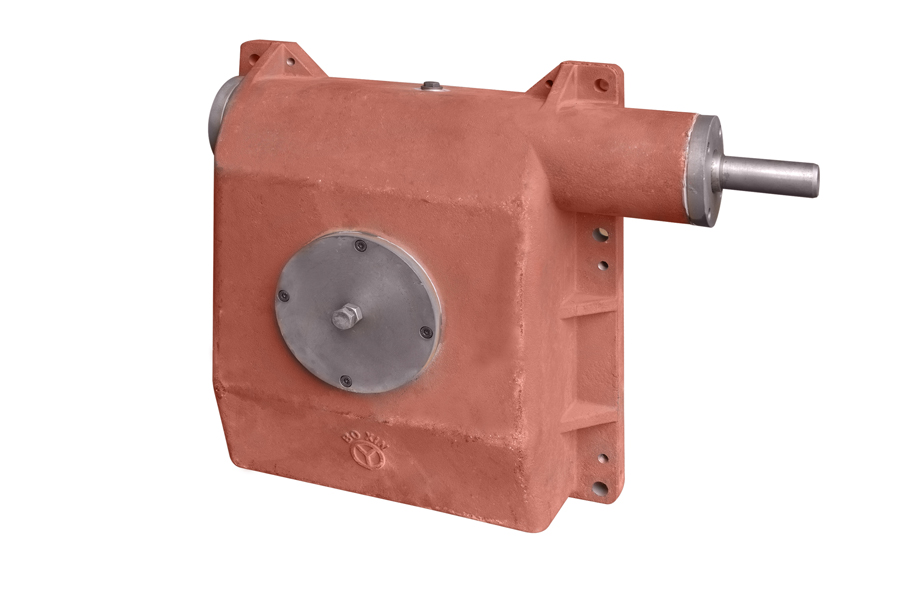

B. Gear: Wear-resistant materials often selected: bronze, copper-clad, ductile iron. If the valve opens and closes frequently and the motor speed is high, it is recommended to use all-copper or copper-clad worm gears. Ductile iron is usually used.

C. Worm: It is not as simple as a worm gear. The conventional use of 45# steel, after quenching and tempering and high-frequency quenching, and then grinding, high torque use 20CrMnTi material worm and bronze worm gear, secondary reduction using spur gear reducer, wear resistance and strength Transmission efficiency can be significantly improved.

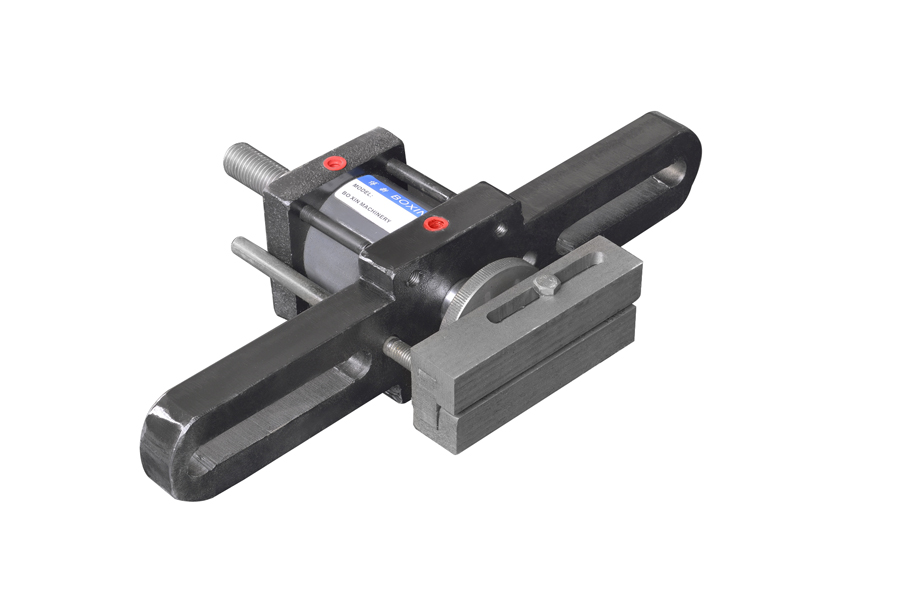

D. Bearings: First of all, the choice of bearing type, the machining accuracy of the bearing position, the worm bearing position, and the bearing position of the worm gear box are the basis for ensuring the stability of the gearbox.The quality of the bearing is also the key to the service life of the gearbox. A poor bearing will jam and lock up when it is subjected to torque.It will rapidly reduce the service life of the gearbox, and it is generally recommended to use a well-known brand.